Four Engines, One Propeller, No Wings

America’s aviatrix, Amelia Earhart [July 24, 1897- July 2, 1937], is now honored worldwide with statues, scholarships, schools, forests, libraries, street names and almost any other way imaginable. Less than a decade after her disappearance during her attempted circumnavigation of the globe with navigator Fred Noonan, the U.S. was entering WWII. America’s Liberty ships included the USAT Amelia Earhart built by Houston Shipbuilding Corporation in Texas. She served during and after that war until she was wrecked during a monsoon off the coast of Borneo in 1948. Rebuilt and sold, the ship is known to have been used as a trading vessel in the early 1950s. By 1965, she was sailing under the Chinese flag known as Jiading.The Jaidingwas last photographed in the docks of Liverpool, England, during 1967, and thereafter disappears from official records. Earhart was again gone but not forgotten.

During 2008, the USNS Amelia Earhart(T-AKE No. 6), was built in the ways at General Dynamic’s National Steel and Shipbuilding Company (NASSCO) in San Diego. T-AKE No. 6 was one of eight ships the U.S. Navy ordered to be built with a primary mission to deliver food, ammunition, fuel and other provisions to combat ships at sea. I lived in San Diego at the time and was allowed escorted tours so that I could photograph the ship’sconstruction.

Building Blocks

The first impression of a shipyard is staggering; the magnitude of construction is overwhelming and the entire process a modern marvel. Through NASSCO’s five-acre shipyard, pedestrians follow the green painted walkway posted with safety warnings to be alert for moving forklifts and trucks as well as pressure hoses, chains, cables and other underfoot cords that are attached to machines and men at work. Everyone is required to wear a hard hat, safety goggles and work boots. A NASSCO fire truck and paramedic van cruise the perimeter of the shipyard in case of an emergency on all three work shifts. The crews communicate among themselves using whistles and hand signals amid warning horns, sirens and flashing beacons of huge equipment. During my first visit, I noticed a blue flag at several different work stations. On my next visit they were red. My tour guide from General Dynamics’ public relations office explained that tool sets were color coded so they could be turned in for inspection while another set of differently colored tools was in use. The flags denoted which tools were in use.

All the steel parts for NASSCO’s ships are made in San Diego but major components like engines and propellers are outsourced. I interviewed Wayne Stevenson, who was then the launch supervisor in charge of every phase of construction to the moment the Navy took possession of the USNS Amelia Earhart.

“Each portion of the ship is individually welded together, painted and then attached to a larger piece,” explains Stevenson. “These sections together form ‘grand blocks.’ Blocks are lifted into place on the ship — outfitted and finished on the interior, then welded to the next block. The hull number of the USNS Amelia Earhartis 476.”

My walking tours began just after the keel had been layed. Over the next few months I identified pieces of No. 476 throughout the shipyard — on the ground, neatly stacked on pallets, resting atop truck beds, rolling off conveyor belts in the machine shop or swaying mid-air from a crane.

“We begin some of the major assemblies before daylight,” says Stevenson. “You can walk by a ship one day and the next it looks totally different. It sounds complicated to do but the process is basic. The ship is recognizable within a few months after laying the keel.”

Two weeks after this conversation with Stevenson, the USNS Amelia Earhart gained a propeller, an entire engine room and another block. On this occasion we paused next to four identical 15-square-foot steel frames bearing chalk marks with encoded part numbers and welding instructions that matched the orthographic drawings in his pocket-sized assembly reference. A fine, straight line generated by computer was scribed across each steel section. Above it were the letters “MRL” to indicate the water level line and a blob of dark green paint to denote that the material is steel. That same day, I saw the unmistakable profile of a ship bottom, marked No. 476, resting upon supports of rough-cut timber. Walking beneath the hull, Stevenson reached up to touch No. 476’s steel that will never again be seen after launch. Wood is essential in shipbuilding. Blocks of Douglas fir brace just about everything under construction. The shipyard recycles the large pieces for chocks and lesser uses until they are finally sold for firewood.

The Japanese Crane’s View

The optimal view of the entire shipyard is 260 feet above from a crane named the Logan Lion (for a local elementary school mascot). The Logan Lionwas made in Japan by the Sumitomo Company and is painted powder blue. I jumped at the offer to see the entire shipyard nestled into San Diego Harbor.

NASSCO’s cranes are some of the largest in the world and they seem to be in perpetual motion. Riding on its own rail system between ways, the Logan Lionis the workhorse of the yard. The crane’s pale yellow “house” on the main platform is accessed by steep ladders, an elevator ride and steps that are only found in lighthouses. The crane operator was a former helicopter pilot who sat in the “cab” to control the Lion’severy move. In the distant and northernmost corner of the docks, I could see recently off-loaded piles of raw steel that would be trucked to the machine shop, cut into parts and delivered to work stations all over the yard. Below me, the USNS Amelia Earhartlooked like a filleted fish, with skeletal steel ribs and brightly-painted innards.

As often as I was privileged to visit the ways, I never got over feeling like a Lilliputian from “Gulliver’s Travels.” Everything was out of scale to the rest of my small world. When the USNS Amelia Earhartwas ready for launch, it was more than 690 feet long with a beam of 105 feet, capable of cruising at 20 knots, and driven by a fixed-pitch propeller powered by four diesel engines.

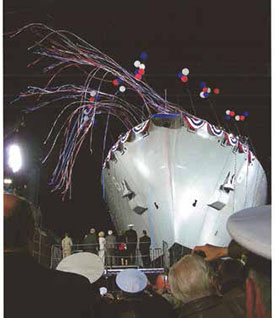

The USNS Amelia Earhart(T-AKE No. 6) was launched April 6, 2008, with Earhart’s niece performing the traditional christening ceremony. I was there to watch the ship slide gracefully into the water, as sirens and horns blew, bands played and streamers and balloons floated from the ship. Fireworks exploded above the harbor.

The USNS Amelia Earhart has a crew of 124 civil service mariners and can include an additional complement of military personnel as needed. Its deck accommodates two helicopters. In keeping with the character of Amelia Earhart, the ship’s motto is “Esprit Intrepide” (Intrepid Spirit).

It would seem more likely that Earhart’s name be associated with an aircraft carrier. However, after serving as a nurse in a Canadian military hospital during WWI, Earhart became a pacifist. I believe she would be pleased that a ship bearing her name now brings aid to others.

For more about Earhart’s life, visit the web site of The International Organization of Women Pilots, the organization she helped form in 1929: www.ninety-nines.org/index.cfm/amelia_earhart.htm.

Giacinta Bradley Koontz is an aviation historian, magazine columnist and author who has received the DAR History Medal and honorable mention from the New York Book Festival. She has appeared on the History Channel and in PBS documentaries. For more information, visit www.GiaBKoontz.com